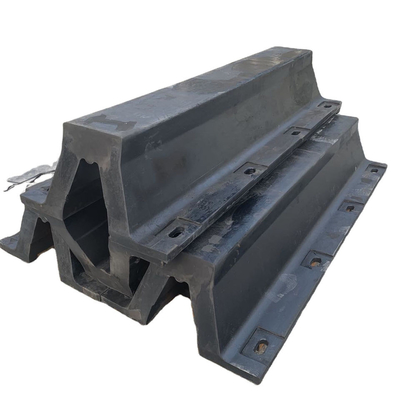

Hấp thụ năng lượng tối ưu với lực phản ứng thấp

Thiết kế hình chữ V cong chuyển đổi hiệu quả năng lượng tác động động học thành biến dạng có kiểm soát, giảm thiểu tải trọng phản ứng lên kết cấu bến tàu. Điều này đảm bảo cập bến ổn định cho các tàu có độ dịch chuyển khác nhau, giảm mệt mỏi cấu trúc và bảo vệ cả tàu và tài sản cảng. Chắn bùn duy trì hiệu suất năng lượng nhất quán ngay cả sau hàng nghìn chu kỳ nén.

Hợp chất cao su gia cố cho độ bền vượt trội

Mỗi chắn bùn được sản xuất từ cao su cao cấp được pha trộn với polyme tổng hợp để tăng cường khả năng chống rách, giữ độ đàn hồi và bảo vệ môi trường. Công thức hợp chất cung cấp khả năng chống chịu đặc biệt đối với ozon, bức xạ UV, nước biển và lão hóa, kéo dài tuổi thọ ngay cả trong khí quyển biển nhiệt đới hoặc ô nhiễm.

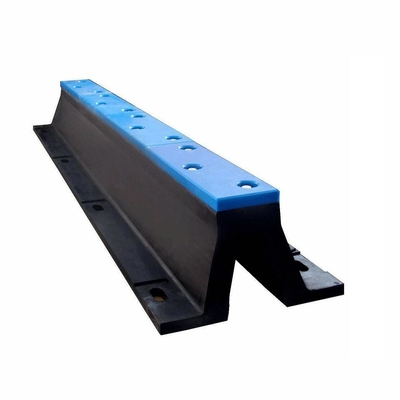

Thiết kế nhỏ gọn và dễ dàng lắp đặt

Chắn bùn hình vòm có trọng lượng nhẹ và dạng mô-đun, cho phép lắp đặt nhanh chóng và an toàn trên cả tường cầu cảng phẳng và cong. Bu-lông neo tiêu chuẩn và tấm thép mạ kẽm cung cấp khả năng gắn chắc chắn, trong khi các tấm ốp mặt UHMW-PE tùy chọn làm giảm ma sát và hao mòn bề mặt. Cấu trúc nhỏ gọn này làm cho chúng trở nên lý tưởng cho các dự án cải tạo hoặc mở rộng với không gian hạn chế.

Hiệu suất nhất quán trên các biến thể nhiệt độ và thủy triều

Độ đàn hồi ổn định của cao su đảm bảo hiệu suất đáng tin cậy trong các điều kiện khí hậu khắc nghiệt—từ nhiệt độ Bắc Cực dưới 0 độ C đến độ ẩm nhiệt đới cao. Ngay cả khi có sự di chuyển của thủy triều, chắn bùn vẫn duy trì khả năng hấp thụ năng lượng và phục hồi nén nhất quán, đảm bảo bảo vệ lâu dài với yêu cầu bảo trì tối thiểu.

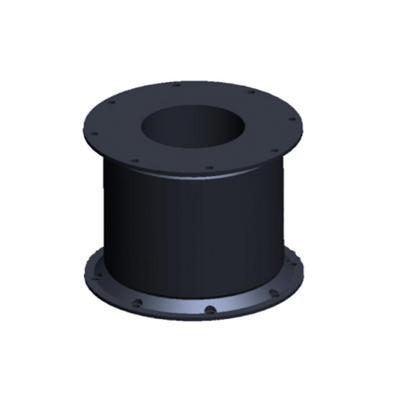

Ứng dụng

Cảng thương mại và bến container

Cung cấp khả năng bảo vệ va đập đáng tin cậy trong quá trình cập bến thường xuyên của tàu chở hàng, tàu chở hàng rời và tàu container. Hình dạng vòm đảm bảo phân phối năng lượng hiệu quả, bảo vệ tường cầu cảng khỏi các ứng suất cập bến lặp đi lặp lại.

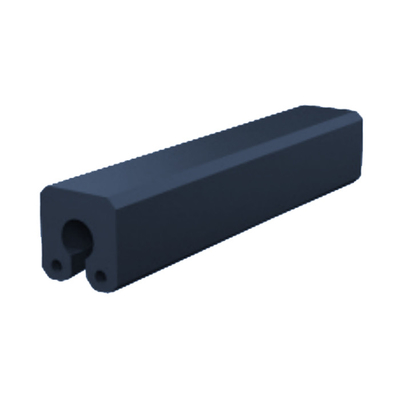

Bến cảng đánh cá và cầu tàu nhỏ

Lý tưởng cho các tàu nhỏ hơn yêu cầu các giải pháp chắn bùn nhỏ gọn, tiết kiệm chi phí và bền bỉ. Các tùy chọn lắp đặt linh hoạt của nó làm cho nó hoàn hảo cho các bến tàu bằng gỗ hoặc bê tông với các điều kiện mớn nước khác nhau.

Nhà máy đóng tàu công nghiệp và cơ sở hỗ trợ ngoài khơi

Được sử dụng cho các ụ khô, bến sửa chữa và căn cứ cung cấp nơi thường xuyên xảy ra tiếp xúc với tàu. Khả năng chống mài mòn cao và hiệu suất ổn định của chắn bùn làm cho nó phù hợp với các chu kỳ hoạt động đòi hỏi khắt khe.

Tại sao chọn Hongruntong Marine

Tiêu chuẩn kỹ thuật toàn cầu và tính toàn vẹn vật liệu

Hongruntong Marine sản xuất Chắn bùn cao su hình vòm tuân thủ các hướng dẫn ISO 17357, PIANC và IALA. Mỗi chắn bùn trải qua thử nghiệm nén, xác minh độ bền kéo và phân tích lão hóa tăng tốc để đảm bảo chất lượng đồng đều và hiệu suất năng lượng nhất quán trong điều kiện biển thực tế.

Công nghệ sản xuất và hợp chất tiên tiến

Chắn bùn của chúng tôi được sản xuất bằng các kỹ thuật đúc và lưu hóa tiên tiến, đảm bảo liên kết hoàn hảo và mật độ đồng đều. Các hợp chất cao su được thiết kế để duy trì khả năng phục hồi cao và độ bền cơ học ngay cả trong các chu kỳ biến dạng liên tục, đảm bảo hiệu suất lâu dài và giảm thiểu sự suy giảm.

Thiết kế tùy chỉnh và tích hợp hệ thống

Mỗi hệ thống chắn bùn được thiết kế theo các thông số hoạt động của khách hàng—kích thước tàu, phạm vi thủy triều và vận tốc cập bến. Nhóm kỹ thuật của Hongruntong sử dụng phân tích phần tử hữu hạn (FEA) để mô phỏng khả năng hấp thụ năng lượng và tối ưu hóa hình học chắn bùn, đảm bảo an toàn tối đa và hiệu quả chi phí. Các tấm mặt trước, miếng đệm và khung gắn tùy chỉnh tùy chọn có sẵn để tích hợp chìa khóa trao tay.

Dịch vụ toàn diện và hỗ trợ kỹ thuật toàn cầu

Hongruntong cung cấp hỗ trợ dự án đầy đủ từ tư vấn thiết kế và lắp đặt tại chỗ đến bảo trì và kiểm tra dài hạn. Với các trung tâm dịch vụ ở châu Á, Trung Đông và châu Âu, mạng lưới hậu cần của chúng tôi đảm bảo giao hàng nhanh chóng và hỗ trợ khách hàng đáp ứng cho các dự án cảng và ngoài khơi quốc tế.

Câu hỏi thường gặp

1. Chắn bùn cao su hình vòm thường kéo dài bao lâu?

Tùy thuộc vào việc sử dụng và tiếp xúc với môi trường, Chắn bùn cao su hình vòm thường kéo dài 10–20 năm với việc bảo trì thích hợp.

2. Chắn bùn hình vòm có thể được tùy chỉnh cho các bố cục bến cụ thể không?

Có, chắn bùn có thể được sản xuất với nhiều chiều cao, chiều dài và cấp độ độ cứng khác nhau để phù hợp với các điều kiện cấu trúc hoặc thủy triều độc đáo.

3. Có cần thêm miếng đệm mặt không?

Đối với tiếp xúc ma sát cao hoặc tàu có vỏ bằng thép, nên sử dụng miếng đệm mặt UHMW-PE hoặc cao su để giảm mài mòn và kéo dài tuổi thọ.

4. Chắn bùn nên được bảo trì như thế nào?

Kiểm tra trực quan 6–12 tháng một lần để tìm dấu hiệu hao mòn bề mặt hoặc nới lỏng bu-lông. Vệ sinh thường xuyên và thay thế các miếng đệm bị mòn nếu được trang bị.

5. Hongruntong có cung cấp hỗ trợ lắp đặt không?

Có, chúng tôi cung cấp đầy đủ bản vẽ kỹ thuật, phần cứng gắn và giám sát tại chỗ để đảm bảo lắp đặt và hiệu suất chính xác.